Incredible Process of Making Wooden Axe Traditional Folded Axes Axe Making

0

0

24 Views

Published on 06 May 2024 / In

Film & Animation

update

Show more

0

Life_N_Times_of_Shane_T_Hanson

Life_N_Times_of_Shane_T_Hanson

TheSaltyCracker

TheSaltyCracker

![Ep 3814a - Supreme Court Making A Ruling On Tariffs, Tariffs Are Reversing The [CB] Agenda](https://cdn.mgtow.tv/upload/photos/2026/01/ec84fa73472bc760b0fcf525a1e82dc28ae16a2cctDxI7WpzRTsBsc9HiCW.video_thumb_high.jpg)

X22 Report

X22 Report

RT

RT

The Alex Jones Show

The Alex Jones Show

Shin

Shin

Matt Kohrs

Matt Kohrs![Ep 3800a - Is The [CB] Making A Move On The Financial System?Trump Continues To Win Against The [CB]](https://cdn.mgtow.tv/upload/photos/2025/12/6834a60a75c1f50f61a8b8796ed628faaa2d2a53vbZ7vmZwfKBIqOcYC72e.video_thumb_high.jpg)

KEEPER

KEEPER

Timcast IRL

Timcast IRL![Ep 3787b - Trump Is In the Process Of Freeing The World From The [DS] Grip, Liberation Day Is Approa](https://cdn.mgtow.tv/upload/photos/2025/12/22e4cd36e11f6785b8b45dee93d9dea4ca7a9fd9lp555RZVohvHjsxrR7zP.video_thumb_high.jpg)

![Ep 3787b - Trump Is In the Process Of Freeing The World From The [DS] Grip, Liberation Day Is Approa](https://cdn.mgtow.tv/upload/photos/2025/12/320ff9865c5f764fa379dc321db05ea5bd114360zDOpK8VSc4wtlsQqYlHp.video_thumb_high.jpg)

Angry Guy

Angry Guy

Log in to comment

When I am watching this, I am thinking, "Here is a method to improve speed, accuracy and higher productivity".

You know like a height adjustable centering jig for the wood lathe, and a high speed, high power drive on that, with a stepped cutting head, that follows a specific set tool path, to bring it to size and profile in a single pass - with round at the top and a tapered flare at the base.

A laquering bath for the finished handles. In / spin / dry and ready to assemble.

A progressive heater - to heat the iron pieces, from cold to hot and into the forging hammer.

A bigger or heavier or hydraulic drop forging - with minimal pass forging dies.

A hardening oil quench for the axe heads - if that is possible - depending upon steel grade etc.

With the 1/2 dozen guys there, I reckon I could make the production 4 or 5 times higher - easily.

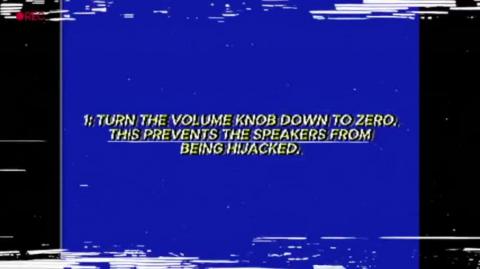

Ax handles need to be made completely different.

Anybody who’s ever swing an ax in their life knows that around even handle will work you to death.